OLI-PUR-CRYL 2K Lackfarbe 13343 - two-component lacquer paint -

Fast drying two-component PU / acrylate solvent-based lacquer paint with excellent gloss and colour stability for monocoat and multi-coat systems in the interior and exterior.

- Very quick drying

- Direct application to steel, stainless steel, zinc, aluminium and GRP possible

- Highly weatherproof

- Excellent gloss stability

- No yellowing or chalking

- Optimum mechanical and chemical resistance

- High bonding strength

- Application by airmix or airless spray gun

- Lead- and chromate-free

The product

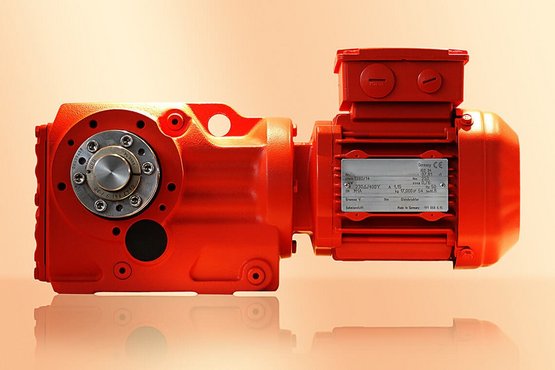

Hoch witterungsbeständige 2K Acrylat-Lackfarbe auf Lösemittelbasis mit ausgezeichneter Glanz- und Farbtonbeständigkeit für ein- und mehrschichtige Lackierungen im Innen- und Außenbereich. Hauptanwendung sind stark beanspruchte Industrielackierungen im Maschinen-, Anlagen-, Land- und Baumaschinenbau. Direkte Applikation auf Stahl, Edelstahl, Zink, Aluminium, GfK möglich.

- Order notes

- Application description

glossy, satin-gloss, silk matt, matt,

10 / 25 kg

N 50/2509

nach RAL, NCS

Surface pre-treatment:

The surface must be dry, clean and free of rust, grease and separators. Test existing coatings for suitability, capacity and bonding strength. Remove defective and unsuitable coatings thoroughly and dispose of them according to the regulations.

Steel/ Stainless steel | Degrease the surface with OLI Universal cleaner 9002; Sandblast rust and rolling skin. When removing rust by sandblasting, proceed in compliance with DIN EN ISO 12944-4, i.e. standardized purity grade SA 2 ½. In case of chemical pre-treatment, follow operation procedures of the producer. |

Aluminium | Degrease the surface with OLI Universal cleaner 9002 and, if necessary, roughen the surface thoroughly (sandblasting, sweeping, sanding). In case of chemical pre-treatment, follow operation procedures of the producer. |

Zinc | Degrease the surface with OLI Universal cleaner 9002. White rust and other oxidation coats have to be removed chemically or mechanically. |

Plastics/ GRP | Wash the surface with OLI Universal cleaner 9002. If necessary, sand the surface slightly and wash again with OLI Universal cleaner 9002. |

Aged lacquer coats | Sand aged, non-defective, non-bleeding and non-thermoplastic lacquer coats slightly. Lacquer coats based on alkyd resins must be fully cured. |

Priming

Priming | OLI-EP 2K Metallgrund 2200 | OLI-EP 2K Metallgrund LAB 110136 |

Bonding to | Steel / Stainless steel/ Aluminium/ Zinc/ Plastics/ GRP/ Aged lacquer coats | |

VOC | 537 g/l | 410 g/l |

ratio (weight proportion) | 10 : 1 with OLI-EP Hardener N 37514 | 5 : 1 with OLI-EP Hardener N 39/1184 |

Spray coats | 1 cross coat | 1 cross coat |

Coat thickness | 60 - 80 µm | 60 - 80 µm |

Drying 23 °C 60 °C | Touch-dry: 2,5 h Ready for installation: 1 h | Touch-dry: 3 h Ready for installation: 1 h |

Top coat OLI-PUR-CRYL 2K Lackfarbe 13343

Application methods | Cup spray gun | Airless |

Spray pressure | 2,5 - 5,0 bar | 80 - 120 bar |

Nozzle | 1,2 - 1,8 mm | 0,28 - 0,33 mm |

Hardener (ratio, weight proportion) | OLI-PUR-CRYL Hardener N 50/2509 (10 : 1) | OLI-PUR-CRYL Hardener N 50/2509 (10 : 1) |

Thinner (addition in %) | OLI-PUR Thinner N 39/3091 (25 - 30 %) | OLI-PUR Thinner N 39/3091 (20 - 25 %) |

Viscosity | 20 - 25 s / DIN 4 mm | 25 - 35 s / DIN 4 mm |

Spray coats | 1 cross coat | 1 cross coat |

Coat thickness | 40 - 50 µm | 40 - 50 µm |