SUPERMATT RAW WOOD LOOK BY AN INDUSTRIAL ROLLING-APPLICATION

OLI-NATURA Scandic Oil-Primer

23.11.2018With "OLI-NATURA Scandic Oil-Primer” reacts OLI LACKE to the industry's increased demand for a new priming-oil which doesn’t intensify the color of the wood and which works for all the common roller-machines. The raw wood effect primer offers an 'invisible' base for the following top coat.

The new "OLI-NATURA Scandic Oil Primer" enables industrial manufacturers to produce natural wood effect surfaces by rolling. The solvent-free primer dries extremely fast, hardens oxidative and ensures a raw wood look. An innovative combination of vegetable oils in aqueous emulsion prevents the color-intensifying of the wood. »No color-intensifying of the wood and no white marking in the pore are the most important distinguishing features of the new »OLI-NATURA Scandic Oil Primer« compared to other products. But also very fast drying is a special plus in the processing", says Götz Schubert, Managing Director of OLI LACKE. Matching top coats create a durable surface protection and a harmonious overall solution from a single source.

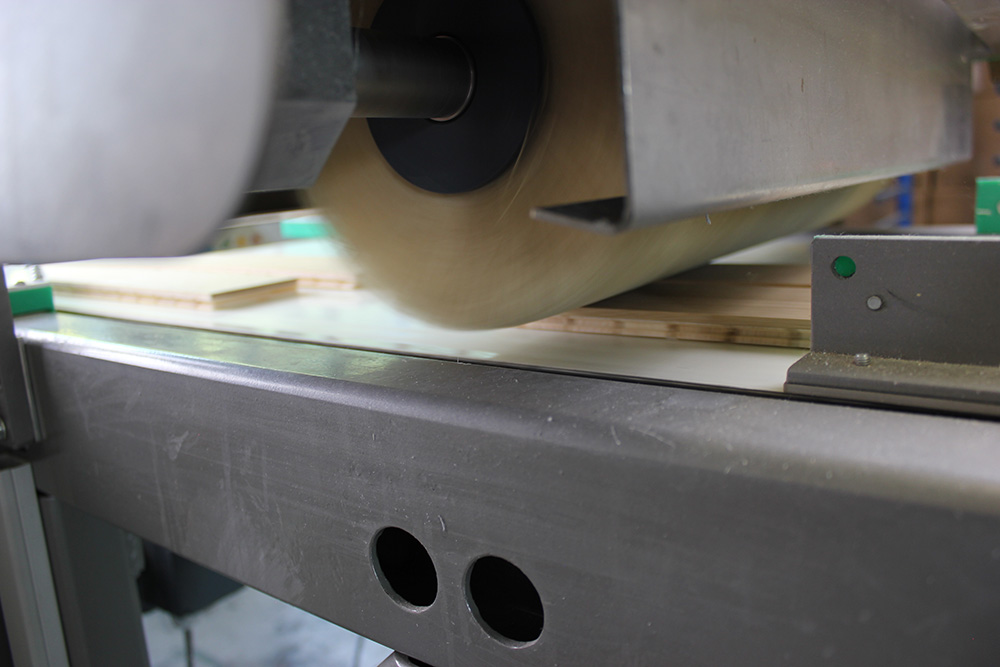

The "OLI-NATURA Scandic Oil Primer" can be processed on all the common roller-machines in the parquet, staircase, kitchen and furniture industries. It is applied in two roller applications at about 25 g / m² using a violet foam rubber roller. Ideally - immediately after application follows a processing with the brush roller to distribute the hydro-oil optimally. Also, rotating pads can be used as a distributing unit. The wood roughening after rolling application is extremely low, so that the application of the second coat – subject to an optimal air temperature in the room - can be carried out after a drying time of twenty minutes, with or without intermediate sanding. The drying time can be increased further by heat and air-circulation, this allows to achieve a high productivity in the finishing process. In order to effectively protect the finished raw wood-like surface from the everyday wear and tear, the application of a top layer is necessary, which can be done on-site or at the factory.

TOP LAYER, APPLIED ON-SITE OR AT FACTORY

For people who like to feel "pure wood" and prefer an open pore structure, a subsequent impregnation on the construction site with "OLI-NATURA Scandic Oil" is recommended. It is applied on the pre-treated wood surface in one coat with about 60-80 g / m² with a roller, an oil applicator or a brush. After about ten to twenty minutes of exposure time, the top coat to be buffed into the wood yet in the wet-phase (by using a white pad) by hand or with a polishing machine until the surface appears evenly dull. The naturally oiled surface looks and feels as if it were untreated and is easy to repair and permeable to vapor i.e. breathable. The wood can absorb and release moisture from the air, which ensures a balanced indoor climate.

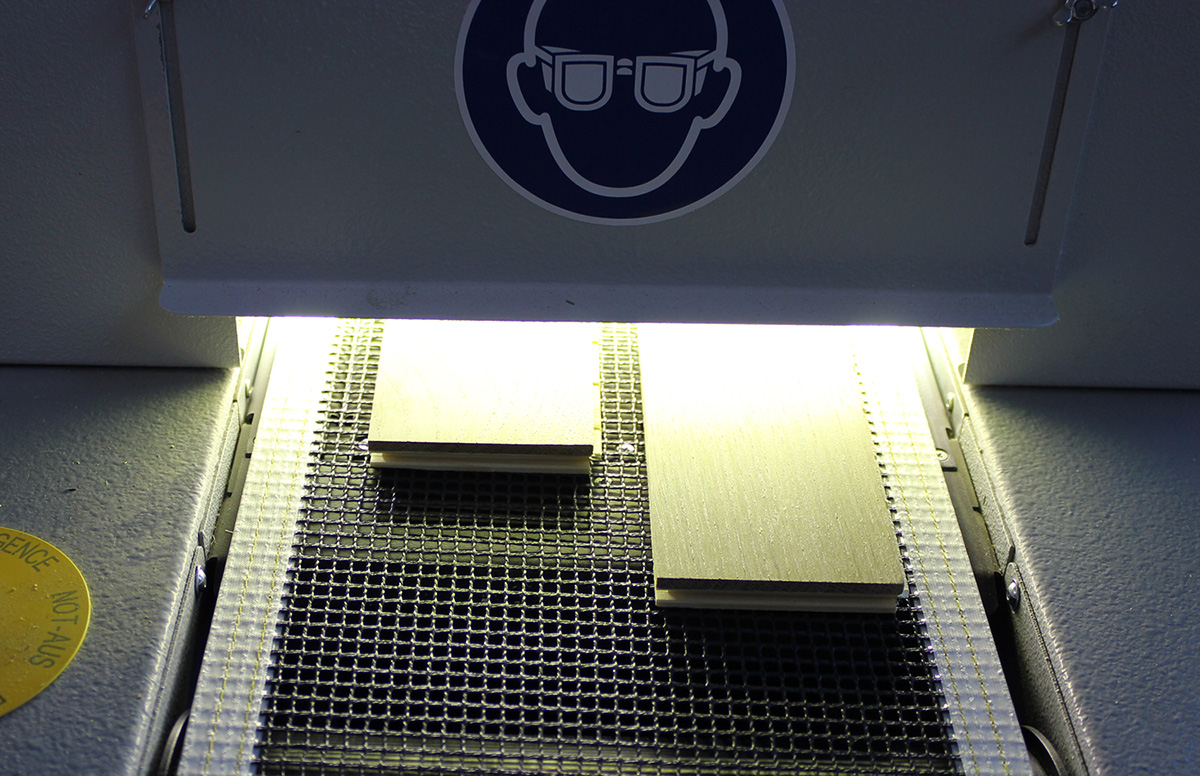

The "OLI-NATURA UV-Oil" is available to the industrial customers for serial and efficient application by UV-rollers. Depending on the desired layer thickness, it is applied on the pre-treated surface in one to two layers with an application quantity of 4-6 g/m² and cures in a matter of seconds thanks to the UV radiation. The degree of gloss is at an angle of 60° at four to six gloss points and produces a natural matt appearance. The finished surface is velvety soft, matt above average and at the same time extremely hard-wearing and easy to clean. This system offers the look of an oiled wood with the care and cleaning options of a lacquered surface.

Press contact OLI Lacke:

OLI-Newsletter

Get all news by email.<br />Once a month, you will receive information about our new products,<br />Relevant processing instructions and object reports.

Sign in now